Promotion for Eric Pfeiffer's Utility Collective

Look around you. Let your eyes rest on the first object you see. Do you know how it was made, and where? The answer is most likely no. And up until a few years ago, it might even have been followed with a “Who cares?” or “Who cares as-long-as-it’s-cheap?”

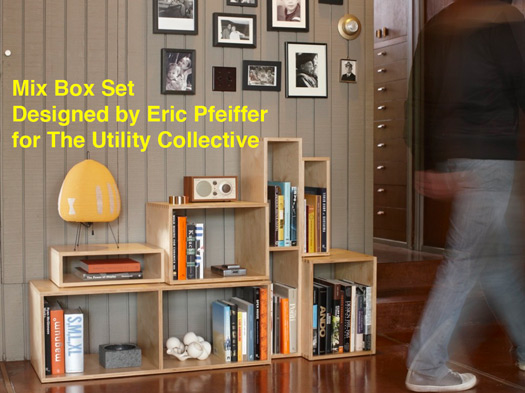

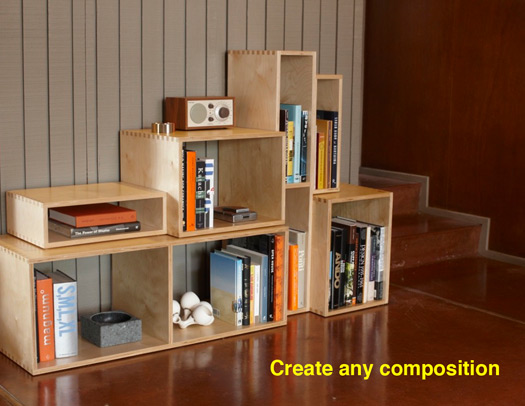

But times have changed, says designer Eric Pfeiffer. He’s gambling that people would care if they understood the story behind the object. He and business partner Steve Piccus are launching The Utility Collective, a San Francisco–based group that makes simple, utilitarian items for the home that aim to do more than just appeal to aesthetics. Mix Box Set, for example, a collection of six modular plywood storage units ($650) — though functional and well made — are not head-turners. But that’s the point. The star of this story is the story.

“Everybody’s talking about sustainability and green products, and there’s all these great materials out there,” says Pfeiffer, a former design director for Offi who co-wrote the ode to plywood, Bent Ply, with Dung Ngo in 2003. “I think if a person understood the complexity and what it took to get that object to them in their home, it would connect in a stronger fashion and endear them to that object.”

Instead of making a first real acquaintance with a product at the store where it was purchased, buyers will be treated to a tale of materials, sourced whenever possible in the U.S., and they’ll learn how the product was made and who made it. Pfeiffer plans to post videos in which he narrates his design process and interviews plant managers and production workers. Step-by-step photographs, even testimonials of customers, will be presented.

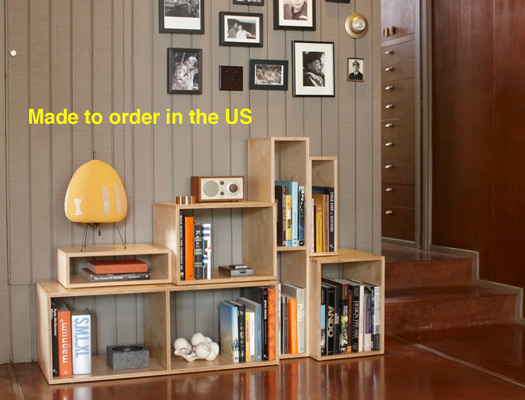

Pfeiffer’s production process is also assuming an intimate character. After designing and building prototypes in his studio, his next step is taking orders. These will be sent to a factory in Arizona equipped with state-of-the art, computer-controlled machines that carve out the pieces and ship them to consumers within four weeks of the time the order was placed.

Such customized domestic production couldn’t be farther from Pfeiffer’s experience of manufacturing in China. There, he had to come up with enough capital to buy a container worth of product, and the goods had to be ordered six months before shipping. He burned time on overseas sourcing trips. The tendency of workers to produce items by hand led to quality-control and efficiency nightmares. If a product didn’t sell, it would languish in a warehouse at considerable storage expense. Consumers had a vague notion of how the product got to the store shelves, if they thought about it at all.

“Buy American” isn’t a new concept, yet the emotional force of local manufacture has particular resonance in these jobless times. Mix Box Set’s price point will be too luxurious for many buyers, but Pfeiffer hopes consumers’ consciences will guide their choices and that they’ll be able to avoid the temptation of cheap, mass-produced furniture that needs to be replaced every few years.

After Mix Boxes, plans are in the works for bedroom storage pieces created in collaboration with Columbia Forest Products. Plywood from trees from Klamath River, Oregon, will be harvested and sent to the same Arizona facility for production. There again, Pfeiffer won’t win against mass-produced goods on affordability. But he’s betting that the story of U.S.-sourced and -made goods will trump price, especially at design-focused niche stores around the country, such as Zinc Details in San Francisco, Velocity Art and Design in Seattle, and Mod Living in Denver.